Vacuum pyrolysis cleaning oven is widely used for removing plastic residues from tools and parts, such as filters, extruder screws, die head, breaker plates, spinneret, nozzles, disc filters, moulds etc.

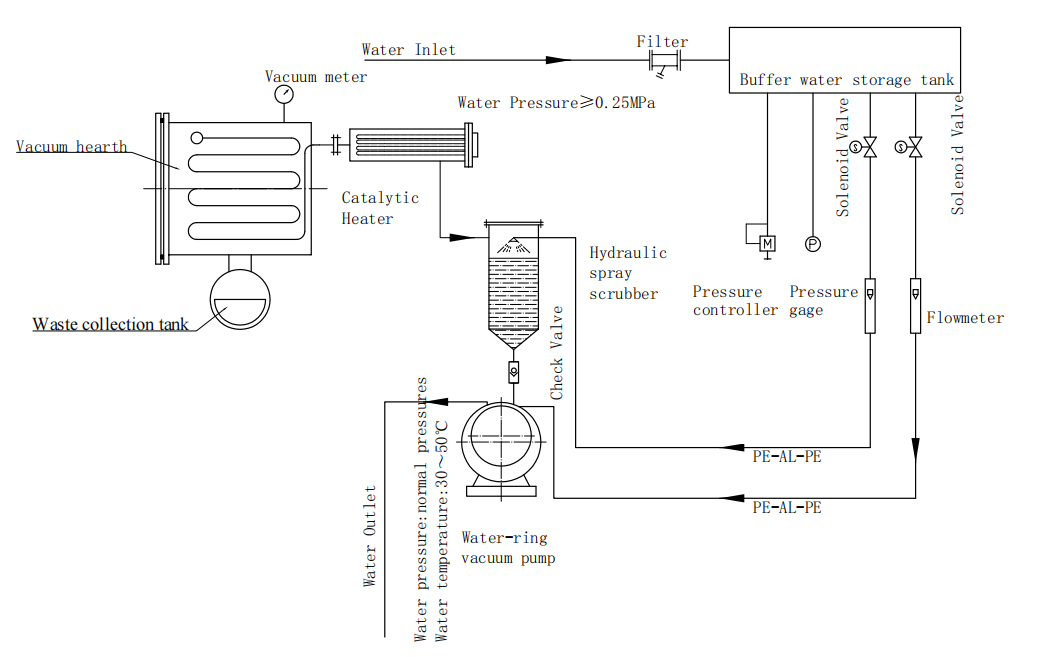

Thermoplastics and mixed plastics are removed under vacuum without any cleansing agent at a variable working temperature. The temperature is precisely configured to ensure the protection of sensitive components. Due to the operation in a vacuum environment, there is less energy loss, resulting in significant energy savings.

■ Fiber industry ■ Polymer industry

Assembled spin packs, Die plates,

Spinnerets, Screen changer die plates with screens,

Assembled spin pumps, Screw elements,

Spin beams, Nozzles

Filter bundles, Candle filters.

■ Extrusion ■ Injection moulding

Extruder Screws, Injection nozzles,

Film Blowing Dies, Screws,

Breaker Plates, etc.. Hotrunner,etc...

Above is for reference, no all are included.

Advantages of Vacuum Pyrolysis Cleaning Ovens

■ Thorough Cleaning: ensure thorough cleaning of objects, even in hard-to-reach areas or intricate shapes.

■ Versatility: can be used for a wide range of objects and materials.

■ Time and Cost Efficiency: automative operation and precise temperature control reduce cleaning time and increases productivity.

■ Environmentally Friendly: acuum pyrolysis cleaning utilizes heat and a low oxygen environment to remove contaminants, eliminating the need for harsh chemicals.

■ Safety: The low oxygen environment prevents combustion, reducing the likelihood of fire or explosions.

■ Improves Equipment Performance: by removing contaminants, vacuum pyrolysis cleaning helps improve the performance and longevity of equipment.

■ Low Maintenance: no need for frequent repairs or replacements, resulting in minimal downtime and cost savings.

Thermal decomposition of polypropylene plastics through vacuum pyrolysis

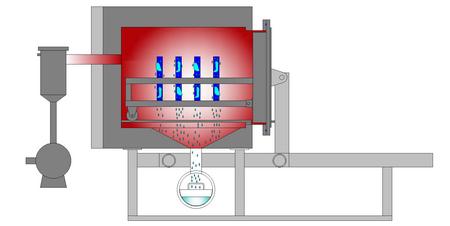

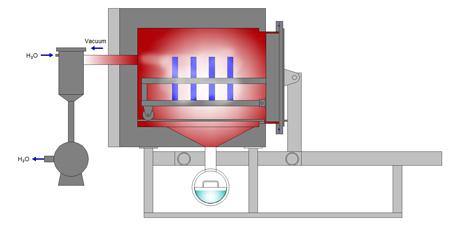

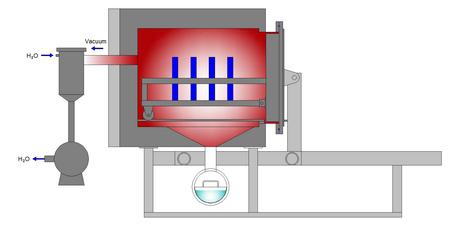

The oven is heated to 300 degrees, and most of the polymers are melted off. The dirty material flows into the waste collection tank.

The temperature is raised to 450 degrees (temperature depends on the material being cleaned), and the remaining polymers will continue to be decomposed under vacuum conditions.

In the state with a small amount of air entering, the polymer is fully decomposed, and the generated gas will be pumped away.

Contact: Ms.Wang

Phone: 86-18351558881

E-mail: vivianwang@saer-tech.com

Whatsapp:0086 18351558881

Add: N150 Kaifangdadao Road, Yancheng City, Jiangsu Province, China

We chat